Recent Articles

-

Christmas Edition of the Digest Out Now

Dec 03, 24 07:52 PM

Custom Made Swords

(at a Fraction of the

normal cost)

In the early days of custom-made swords, particularly around 2008, some Chinese eBay sellers began offering customization options to boost sales. Unfortunately, many of these ventures ended poorly, with items either arriving incorrect or not at all...

Despite this, an intriguing experiment with a lesser-known forge led to the creation of two prototype katana. The positive reception of these prototypes led to a series of 21 limited-run batches from 2008 to 2012, each offering tens of thousands of possible combinations. This ambitious project was a significant undertaking and was mostly done at cost, but the stress of managing such a large endeavor eventually led to a decision point in early 2013.

The SBG Black Dragon Forge is now back, bringing custom-made swords to enthusiasts worldwide with free shipping. Each sword is crafted from T10 tool steel, differentially hardened to display a natural, prominent hamon. The customization options are vast, allowing for personalized blade lengths, fullers, and handle materials, among many other features.

This renewed endeavor is driven by the enthusiastic feedback of past and present customers, aiming to blend tradition, innovation, and high-quality craftsmanship in every blade - and below, the story of how it all started and what to expect if you were to order one of these custom made swords today...

SBG Design Your Own Custom Katana

Review by SBG Editor in Chief, Paul Southren

The custom made swords in this review were originally designed for my own personal gratification - but became the basis for our SBG Design Your Own Katana range. Made by a little known but highly skilled and experienced forge in China that usually produces much higher end offerings, the project grew from offering the same design process to a select group of close friends to massive group buys consisting of batches of up to 100 swords at a time - so popular that these batches would fill up in less than a week (which is understandable considering that we often sold them at cost price).

The two custom made swords I will be reviewing below were the original prototypes for this series and made for me back in 2008. Since then, the forge and the available options have come a long way. But the principle has always been the same - take a T10 tool steel Katana blade and select it's configuration and components from a list to create your own unique design.

For these prototypes, I chose one of each broad type on offer - one is with bo-hi (fuller) and best described as light, fast and agile and the other has no fuller (no-hi) and was designed to be a real power cutter.

Naturally, all the frilly customization options would not mean a thing if the blades were sub-standard. So let's take a closer look at them.

The Blades

When deciding on what kind of blade to use as the base of my SBG custom made swords, there were a couple of considerations. The first was tradition - I knew it was possible to produce an authentic, differentially hardened blade with real hamon for a reasonable price so it had to have that. But the other equally if not more important consideration was edge retention and durability.

I believe that I found the solution to creating a hard, yet ductile blade by using T-10 Tool Steel, a kind of Tungsten based steel with between 0.95 and 1.05% carbon content that is usually only found on high end blades in the $1,000 price range.

As you can see, the hamon line of these blades is extremely prominent one of the benefits of T-10 is how it really brings it to life and it is polished with a very (very) smooth 3000 grit finish.

Apart from the attractive hamon, the real advantages of T-10 steel is that because it is a high speed tool steel, the edge especially if it is differentially hardened (as these blades are) - can take and hold a much sharper edge for longer than most other steels. As far as blade hardness on these custom made swords goes, the edge is 58/59 HRC and the spine 41/42 HRC.

However the other advantage of T-10 tool steel is that it also makes the blades very scratch resistant, while retaining a ductile core to allow the stresses of cutting to be absorbed without creating an overly hard and brittle blade (aptly demonstrated later in the review).

Anyway, with the choice of steel and tempering method pre-determined, the first option with these custom made swords is to select the blade length either 27, 28 or 29 measured from the habaki (blade collar). In my case, I selected standard length 28 blades for both.

The next option was to select a bo-hi (fuller/blood groove) or no-hi (unfullered/solid bodied blade). For these two demo swords I selected one of each the bo-hi version for speed and agility and the no-hi blade as a power cutter.

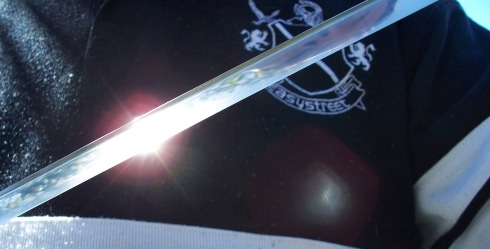

As mentioned before, the polish of these custom made swords is very even and consistent. Indeed, both of them were so smoothly polished and reflective that they can do the famous predator trick of appearing almost invisible when reflecting tree branches as I did with the $2,500 Yasha Katana by Musashi Swords.

Above is the bo-hi version, below the solid bodied configuration.

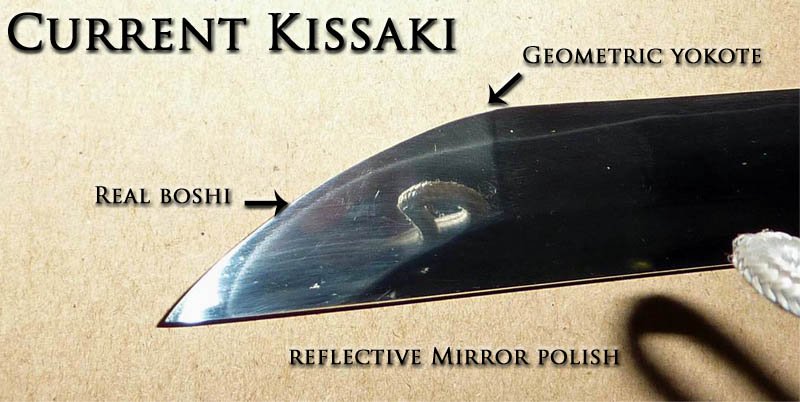

The Kissaki (tip) is decent enough considering the price point, a little rough perhaps, but with boshi (tempering to the tip) and as sharp as a scalpel...

Not satisfied with the typical counter-polish, we spent a small fortune refining the kissaki polish and added in a geometric yokote - improvements NEVER seen on swords at this price point.. Now all SBG forge blades have a mirror polished kissaki that matches the blade.

Considering how low I have squeezed my margins on these, I would say that it would not be unreasonable to sell the blades alone in Shirasaya at the $300 price point, and in many ways, the customization options that are next are a SERIOUS bonus!

Choice of Fittings

Now here is where it gets very interesting.

So far for our custom made swords we have the choice of blade length and whether you want a fast and light blade or a heavier and sturdier on.

But now we get to decide on exactly how we wish to personalize it and make it truly a unique one of a kind Katana.

Essentially, you select what tsuba, fuchi/kashira, ito wrap, rayskin color and saya you want to go with your sword and the forge does the rest.

When you consider the number of combinations, the chances of someone else picking the exact same type is statistically about 1 in 6,000,000!

In my case, I opted for two styles:

Sword 1 - the bo-hi version

Sword 1 - the bo-hi versionThe first one (pictured above) is a 28 blade (measured from the habaki) with bo-hi, Type P23 (claw) Tsuba, C6 Sakura Fuchi and Kashira fittings, standard black cotton ito with white same and a glossy black saya. I made the selection with my wife, as she wanted something that was quite traditional but the unusual tsuba gave it just a little more character.

The second one was to be my heavy duty cutter.

Sword 2 - the solid bodied blade

Sword 2 - the solid bodied bladeSo again I selected a 28 blade but this time with no-hi and gave it a bamboo theme P12 bamboo tsuba, C8 bamboo Fuchi/Kashira, brown ito with white same and textured black saya.

So lets take a quick look at how these two custom made swords turned out.

Bo-hi Version

The lightweight bo-hi version has a streamlined, sleek appearance. The black cotton ito wrap is very tight and evenly done, with nice even strips of same (rayskin) on both sides and double pinned with two bamboo mekugi as standard.

The fittings were solidly assembled no looseness anywhere else and very nicely put together. Naturally I disassembled it to make sure that all the components were structurally sound, and found everything to be in good order.

The friction fit was tight for about the 1st half of the nagako but not prohibitively so and all components were in good condition.

So far so good...

The brass tsuba is definitely a unique design, with a somewhat rustic feel to it and it definitely has a lot of character. There was a little flash from the casting here and there, but overall it looks great, even if I still cant figure out exactly what it is supposed to symbolize (I call it the claw!).

The saya is pretty nice with a traditional shiny black lacquered gloss finish.

A nice touch is the golden colored shitidome, which gives the saya that dash of color and character.

The fit to the sword is acceptable. By that I mean, a little tight (both were a little tight actually) but as anyone who has handled Katana for any length of time will know, the wood on all swords needs to be adjusted from time to time and better too tight to start with than too loose...

Not perfect, but perfectly acceptable if you know what I mean.

No-Hi Version

This was the Katana with the bamboo theme, and the forge translated my vision of this sword perfectly.

Again, the ito was very tight and everything on this one gave it a rock solid feel.

To keep things simple, the menuki (ornaments) are chosen to match the overall theme you have selected, so in this case they were (naturally enough) bamboo.

The themed brass tsuba looked great again very rustic and antiqued in overall appearance and it suited the choice of fittings and color combinations perfectly.

Of course, as these are custom made swords, if you choose a horrible combination you are kind of stuck with it, so spend a little time thinking about how it will all come together and try to blend the different components together as smoothly as possible. (Of course, there is nothing stopping you from picking a dragon themed tsuba with bamboo styled Fuchi/Kashira, green/white tartan ito and bright yellow saya but the less random and more deliberate, the happier you will be I think!).

The saya was particularly cool.

I personally prefer the textured pebbled style of saya as they dont leave nasty fingermarks or scratches on them and just look, well, cooler.

Again, this design had shitidome and the color of the sageo (cord wrap) matches that of the ito wrap.

So thats what my two unique, one of a kind custom made swords looked like. But how did they handle, and how do they cut?

Well, I am glad you asked...

Handling

Now weight and balance will vary slightly depending on the type of tsuba you choose, length of the blade and bo-hi. But just to give you some idea...

The bo-hi version I had made weights 2.2lbs (2lbs 3oz, 1kg) and has a point of balance 4.52 from the tsuba, while the no-hi version weights 2.5lbs (2lbs 8oz, 1.15kg) and is balanced at 5.1 from the tsuba.

The difference in handling is like night and day. This may sound biased, but the bo-hi version is the most lively and agile Katana that I have owned to date, while the other one of my custom made swords feels powerful and authoritive.

Of the two, I actually like the speed and handling of my bo-hi version the most. It also made an extremely clear and fearsome Tachi Kaze (sword wind sound) when it whooshed through the air. I honestly found it hard to put the bo-hi version down.

The thing handles like a dream, and as we will see, cuts like a light saber...

Testing

Now I am not sure if I mentioned it before but both of these blades are evenly polished with a 3000 grit finish, and they are also uniformly sharp. And not just a little bit sharp either...

T-10 Tool steel is excellent for its ability to take and keep a paper cutting sharp edge. But as you can see from the video below, suspended paper can be sliced to er paper thin size slivers without so much as breaking a sweat.

VIDEO: Cutting Suspended Paper

Only the sharpest and most balanced swords can cut suspended paper. And this one did it with a speed and precision that is nothing short of extraordinary .

Naturally enough, being so well balanced and sharp, both swords made short work of light targets such as water filled bottles in a variety of shapes, sizes and quantities, sailing through with a minimum of effort and leaving crisp lines in their wake.

VIDEO: Slicing and Dicing Water Bottles

Such clean cuts that when you pull them out of the water container, it stops dripping .

But of course, the most important targets were the traditional ones Tatami Omote.

Despite my crappy form, I found that both swords sliced Tatami with the slightest impacts. Some of the cuts I performed saw the top of the mat hang for a split second before falling away to the ground. I am sure that someone who was actually skilled in the Japanese sword arts would be able to do some very fancy cuts with these blades.

But alas, not being formally trained, all I could do was to have a little fun and spend an afternoon cutting the mats into pieces.

VIDEO: Tatami Mats

Despite my poor form, both swords performed exceptionally well cutting Tatami

Now of course, if this was any normal review, I would have just left it at that. These custom made swords are well assembled, with excellent handling characteristics and razor sharp blades that make short work of light and traditional targets with ease...

But the fact of the matter was that as these custom made swords were to bear the official SBG name, I had to make sure that they were more than just adequate and some destructive testing was in order...

To be perfectly honest, I actually didnt want to do it to them. But it had to be done, so I decided that I was going to keep the speed demon bo-hi sword in perfect condition, and took the bamboo themed to the sacrificial altar...

Destructive Testing

Initially, I didn't want to share the results of these tests, not because they were bad but because they were actually surprisingly GOOD and it was my fear that showing them would encourage people to abuse their blades.

After all, these are traditional Differentially hardened blades, and as anyone who knows anything about them will tell you that they are simply not flexible so that if you stuff up a cut, you run the risk of bending the blade. And that the razor sharp edge often comes at the price of being somewhat brittle...

So while destructive testing on a precision implement like a traditionally clayed and hardened Katana usually last all of 5-10 seconds a series of extremely challenging targets produced some surprising (and rather shocking) results.

Indeed, after cutting this tree branch and slamming it into woodblocks and the like, I continued pushing the blade until it sustained some actual damage...

Like I said, I didn't really want to show all these tests. And I did a lot more to this blade that what I am showing below, but I think that the results speak for themselves and demonstrate that these custom made swords are more than adequate for day to day cutting practices...

VIDEO: Destructive Testing

Please DO NOT do this at home. Destructive testing is extremely dangerous and should only be performed by someone who knows how to escalate and evaluate a sword progressively.

Conclusion

Did I achieve by goal of creating a range of custom made swords with good quality blades with their own unique choice of fittings made in the shortest time possible, for the lowest price and maintaining a decent level of both performance and durability?

Well, the quality of the blades is unquestionable. The choices of fittings is

wide enough to create some very unique, one off designs. And the price is VERY reasonable.

Performance and durability considering that the bo-hi version is honestly the best handling Katana I have seen in this kind of price range to date, and the solid bodied one can cut through a solid tree branch with one clean slice and withstand impacts to a 55 gallon drum, I should say so...

So that just leaves one thing time, and also consistency of quality...

Each of these custom made swords is produced to order from forging the

blade length and fuller to mounting the fittings, and then shipped to all the places you can still ship swords to direct from the

forge in China in a no-frills form fitting polystyrene protective

box (with no margin to speak of, we did not want to waste money on a fancy box - we just wanted to get the sword to the end customer without it being damaged in transit).

The form fitting polystyrene box

The form fitting polystyrene boxThe time between ordering and receiving your sword is typically 2-3 weeks, down from months when we first started (though please allow for minor unexpected delays of a week or two, maybe more on orders that go for the higher end saya options).

So to answer the question, yes I believe that I DID achieve my goal of creating custom made swords with a range of options to give the Japanese sword enthusiast on a budget a sword that would normally cost at least double the total price I am charging...

Are these swords the be all and end all? Well, there will always be a market for much more expensive custom made swords, and I am not pretending that these swords are perfect. But for the money, I seriously doubt that you will find a better deal, and I am very proud to have created this line which are effectively everything that I personally wanted in a decent entry level Katana, and then some...

PROS

- Available in YOUR choice of fittings and colors (around 24 million different possible custom configurations!).

- High quality T-10 Tool Steel Blades in two configurations and from 26 to 30"

- Traditional Differentially hardened blade with natural hamon

- Solid fittings (all iron) with tightly wrapped ito

CONS

- Wait time: while it takes 2-3 weeks too typically make and ship the sword, actual transit times can also be in the weeks. It is still not the many months wait time we saw in the early days of offering custom made swords to the community, but it is not an 'instant' custom katana..

- We can't bring our selves to give our own product a 5 star rating here as we know there are small things we can do to tweak it and make it even better.. But if we do these things, the base price goes up - and so we must accept the price limitation and just deliver the best we can for the money spent.

WHERE TO BUY

The SBG Custom Katana is of course exclusively available here at the SBG Sword store for just $299.95 with free worldwide shipping!

You can also check out a gallery of past projects made here

I hope this information on these exclusive custom made swords has been helpful. To return to A Beginners Guide to Authentic Japanese Swords from, Custom Made Swords at a Fraction of the normal cost, click here