| Back to Back Issues Page |

|

|

Sword Buyers Digest - October 2012 October 01, 2012 |

| Hey,

As such, this month’s issue gives you a sneak peek of the reports, videos and photos we have to share with you all – and then our usual mix of bits and bobs to gear everyone up for a swordy Halloween. So settle in folks, it’s about to get VERY interesting I think..

CONTENTS

1. From the Desk of Paul Southren Well, where do I begin! My trip with Chris from Ronin Katana was, in a word, amazing.

It’s very much a place few Westerners or outsiders actually ever go to. As you may remember from the previous issue of the digest with the google map it’s not an easy place to access, 4 hours by a car through the mountains – so if anyone says they ‘flew into’ Longquan, don’t believe them! It’s not that easy I assure you!

Our ride was provided courtesy of our friend Weiping “Jack” Zheng, who is one of the premier sword makers in Longquan (and indeed, the whole of China). Jack welcomed us with open arms and really peeled back the lid on the production sword process, allowing us unprecedented access to his forge and how the sword industry in China really works..

L to R: Paul, Weiping “Jack” Zheng and Jacks translator and niece, Ms. Lily Ji. Indeed, I am still trying to digest all the information that was presented to us – to see swords being made at so many different levels, from cheap anime swords cut from sheets of steel with welded on rat rail tangs to meticulously made blades forged and polished by accredited masters, they can – and do – make it all. And we saw it all. So let's take a few moments to share a few highlights from the trip ahead of all the official videos and write ups that are pending and that will be released over the coming weeks and months (because honestly, we learned and were shown so much that it will really take that long to format and compile it all!). Starting with..

Naturally enough, with a price tag in the tens of thousands of dollars, you’d expect it to be something special. But words do not do justice to this stunning piece that was the first sword we saw in Jack’s office. It was literally jaw droppingly gorgeous.

This piece is actually poised to be sent to the Museum in Leeds as a faithful replica of the original to go on public display. Jack showed it to us to demonstrate that forge can, and does, make anything depending on what the requirements and budget of the customer because at this forge they make swords that are sold under many different brands (Ronin Katana is obviously one of them, but there were a lot of other branded names being made here too).

FROM RAT TAIL TO MASTER FORGED The amount and variety of swords made at the forge is staggering.

But equally staggering - unlike some of their sellers, Jack and his staff were totally upfront about the different production techniques used for functional versus cheap ornamental swords and made no illusions about the limitations at each price point. If a company wants a ‘basic’ blade cut from milled steel and mounted with zinc alloy fittings, they will do it. Indeed, as Jack said in his exclusive one on one interview with me (video coming soon!) what they make depends on how much time needs to be spent on each sword combined with cost of the raw materials. In short, you get what you pay for. For example, on the ground floor of the building is where they make the basic swords, polish them and mount them at various rooms and work stations.

But upstairs, the rooms are quieter and cleaner, and it is here that you will find the master polishers who have trained for 6 years to get to where they are and who spend a FULL WORKING DAY hand polishing a SINGLE sword.

BUSTING SOME MYTHS AND CALLING BS The goal that Jack, Chris and I share is to try and get as much factual information out there about how the swords are made so that people can make an informed decision and to cut through the marketing BS employed by some brands. For example, I asked about Japanese Made Components being sent to China and the answer was that no-one does it. He said that basically, they buy a lot of them from a local supplier who makes everything locally, but the larger forges also make their own fittings. The habaki press in particular blew both Chris and I away. To see the press stamping out habaki from brass sheets like that was something else.

Anyway, the point is – if someone says it is ‘made with premium Japanese silk’ or alludes that the fittings are made in Japan, unless it has been refitted in the US you can safely call BS on it.

Our goal is to simply try and sort fact from fiction and make re-branders more honest and accountable so you can buy a sword that suits your budget knowing its limitations or intended useage. No more "$200 swords forged by Master Smiths in Longquan", "Premium Japanese fittings" or lies about what kind of steel is used. By the time this info is all released, you'll be able to tell if something is true or not based on the final price - and the more people know, the more we can squash BS marketing to make it unprofitable and lift the industry standard, which is good news for you, me, honest brands and the forges! So in the future, we hope to see less of this kind of thing..

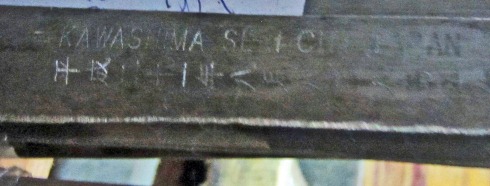

They ain't made in Japan, that is for sure - this is just a decoration, if the rebrander wants to pretend they are made there, it's just a lie - and one that we hope soon will become less and less easy to get away with...

PROJECT X One of the official reasons to go to the forge in the first place was to oversee Project X, the dual project between Ronin Katana and SBG. And I am pleased to say it is going very, very well - here's me holding one of the first completed blades.

It was upstairs with the master forged, master polished blades and the other more expensive and or exclusive stuff (upstairs was a bit tricky, they didn’t really want us to up there – but mostly because the roof was a bit low, I bumped by head going up and thought that I’d go through the rather light wooden floor!) so I brought it down to get a better look.

As expected, the blade was a real beauty and the forge were justifiably proud of their work. We then moved on to the tsuka – it ended up costing considerably more than we originally priced it but we needed a FULL rayskin wrap, and they wanted to make sure we were happy with it.

I think you can safely say that we were! You can see some really big emperor nodes in there from the sting ray spine, I asked one of the workers and you usually get 4 tsuka to one ray, but this one is made from an entire skin! Jack was a little concerned that doing the full wrap, which was rarely done due to the cost, would cause the tsuka to bulge funny a bit when wrapped, but we explained it did not matter because we wanted the extra reinforcement this gives the whole tsuka assembly. But just to be on the safe side, we had it wrapped to see (even using some Hishigami) and it turned out just fine.. I am REALLY liking the direction this project is taking, that is for sure..!

MUCH, MUCH (MUCH) MORE TO COME Like I said it’s going to be quite a while before we get all this info out there – and these are just a few quick things off the top of my head and working trying to get the digest out within a very tight time frame. It's not even the tiniest tip of the iceberg, just a tiny sampling of what is to come... So for now, here’s a quick video of how we finished off the last day, with Jack, Chris and myself doing some cutting on that crazy thick bamboo that I have ALWAYS wanted to cut but never had the chance to until now (we cut in a patch owned by Jacks friend who makes display boxes). Jack cut it straight off and made it look easy, Chris and I struggled and unintentionally abused the heck out of the sword, but it didn’t mind. It was really cool to have the guy who makes the swords and the guy who sells them actually cutting with them.

It truly was an amazing trip - so many things were definitively clarified for me like never before, and in many ways I learned more in those jam packed three days than I have in the last 7+ years of running SBG..! So next, to get that info out to YOU - so stay tuned folks. Very exciting times ahead indeed...

Naturally enough, with Halloween around the corner this month, my mind turns to Zombies. Well, like most sword lovers, my mind turns to zombies fairly often anyway, but at Halloween the old staple of sword vs zombies tends to become a more frequent theme – and in this months VoM we take a rather gory look at some simulations by youtube channel, ZombieGoBoomTV of a sword vs a baseball bat against a their zombie simulator.

Continuing our Halloween theme – this month we will be taking a look at some ‘scary’ swords. And by that I don’t mean swords that are really badly made, I mean of course ‘Scary’ swords with a dark and scary Halloween theme listed at some of our favourite, recommended sellers.

Purely ornamental due to its stainless steel blade, but as you may have seen from my REVIEW of this piece it is extremely well constructed, and is the perfect decoration to set off a Halloween party. The detail on this sword has to be seen to be believed, it really is very ornate and due to its size is both intimidating and visually striking. Available at the best price online here at Trueswords.com for just $104.99 – you can also find a wide variety of cheaper ‘dark fantasy’ styled ornamental swords at Trueswords perfect for trick or treating (as carrying around a truly functional blade is probably not a very good idea). The captive skull sword below for under $50 being another very aptly themed Halloween pick that is kind of fun and not too expensive for what it is I suppose.

Check out their full range of Halloween suitable fantasy swords here Oh, and while you are there you can also pick up some cool novelties like ‘blood pack’ themed caffine drinks, skull mugs, etc all at a very reasonable price in their novelty section here

ZOMBIE PREPARADNESS Of course, the true sword aficionado knows the inherent danger of Halloween – and how if the zombie apocalypse was to start on this day, it would be very hard to be able to separate those costumed as zombies from the real thing. As such, it is probably the best idea to have a zombie preparedness kit somewhere close at hand just in case.. Again, Trueswords comes to the rescue this Halloween with page of affordable, practical options. From Khurki, Machetes, Axes, Survival gear, gas masks, fire starters, and much, much more – they have listed it all on one page here so best to get any last minute life savers now – just to be on the safe side.. Trueswords Zombie Defence Section

From the movie Sleepy Hollow, this Windlass sword IS the real thing – with a carbon steel blade and decent, well assembled fittings in a suitably dark, snake like theme. This one can be hard to source, but it is available direct from the manufacturers retail arm – Museum Replicas for $195 (with a $19.50 discount if you use our discount coupon code ‘sbg-web’). And while you are there, MRL also have a very large range of costumes – for children, men and ladies – from a dark monks get up to Jedi suits (oops, I promised I would not talk about Jedi again for a while, lol) MONTY PYTHON (yes, the black knight does always triumph) and much, much more. Check out their full selection here

Phew, a pretty big and intensive issue – but it’s only the beginning folks. Stay tuned, and until next time, happy swordening all. Paul Southren |

| Back to Back Issues Page |

I’ve literally just come back from my trip to Longquan to see how swords are made over there, and my goodness – we were given unprecedented access.

I’ve literally just come back from my trip to Longquan to see how swords are made over there, and my goodness – we were given unprecedented access.

HESSIAN HORSEMAN SWORD

HESSIAN HORSEMAN SWORD