Recent Articles

-

Christmas Sword Buying Guide 2025

Dec 03, 25 10:53 PM

Project X

Best quality swords without the massive mark ups

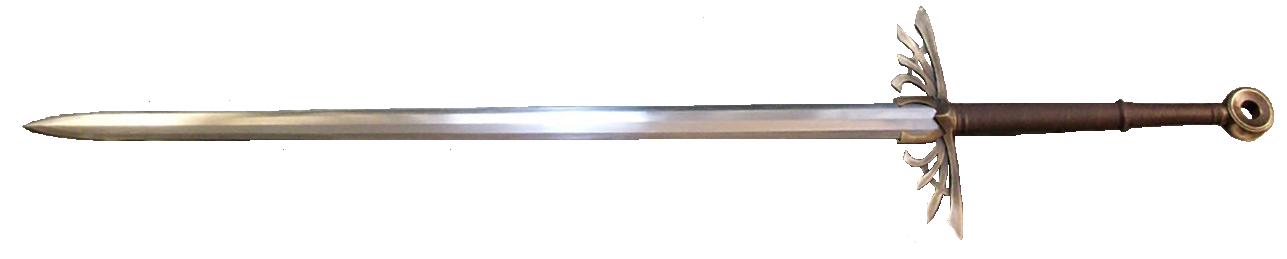

An example of just SOME of the features of a Project X Katana

An example of just SOME of the features of a Project X KatanaProject X started as a partnership in late 2011 with Chris Scoggin from Ronin Katana, who had been working with two Chinese Master Smiths to produce his line of

'Ronin Elite' swords, and we decided we wanted to try offering these blades with a choice of custom fittings in the official SBG Sword Store.

The end result of this collaboration is basically a very special, limited availability run of made to order, semi custom Master Smith forged Katana that expanded to encompass other Master Smith made product lines..

And here is the backstory of how and why it came about, along with some twists, turns, drama and much more!

So let's dive straight on in..

FEATURED ARTICLE:

Evolution of the Japanese Sword Market in Longquan.

From Blue Collar to Master Smiths taking it to the next level with Project X…

Apprentice Sword Polishers working on your typical $200-300 Katana. They don't exactly look very enthusiastic or professional. As you can probably guess, these guys don't work on Project X.

Apprentice Sword Polishers working on your typical $200-300 Katana. They don't exactly look very enthusiastic or professional. As you can probably guess, these guys don't work on Project X. Compare this with a MASTER Polisher who trains a longer apprenticeship than a sword maker, working quietly by himself and spending the whole day on a single blade..

Compare this with a MASTER Polisher who trains a longer apprenticeship than a sword maker, working quietly by himself and spending the whole day on a single blade..Over the years I have seen a lot of "Japanese styled swords" made in China.

Most have been 'okay'. Some pretty solid and dependable. But so many more just left me shaking my head wondering ‘what WERE they thinking when they made this piece of crap’.

I’m sure if you have been collecting for a while, you know what I mean. From stainless steel, one screw holding it together, rat tail tang horrors to carbon steel blades that just felt WRONG and the geometry was so messed up they couldn’t cut their way out of a paper bag..

In 2005 when SBG started, you had to look pretty hard to find good quality swords.

Choices were limited to stainless steel wallhangers (which cost as much as today's REAL swords) and then just pretty much the Hanwei Forge PPK, Cheness (which had just started in earnest), Last Legend (long gone) and the occasional diamond in the rough like the legendary Masahiro Bamboo discovered by Marc Ridgeway on SFI.

By 2008, there were new sword designs, brands, sellers and sword makers were popping up all over the place!

For the real lowdown on eBay sellers, click here - or HERE if you want to see some examples of some of their worst work and business practices.

eBay swords and going direct with the Chinese forges started something

of a

revolution. Some people got some really amazing stuff. Others, got

ripped off (an unfortunate side-effect – hey, it’s the interwebz!). Most

got something in between - not great, but not that bad either. And a few, well they just got ripped off completely or wondered why the guy who had been so helpful leading up to the order was suddenly no-where to be seen if there was a problem..

Personally, I didn’t really like this so much - and I imagine a lot of other enthusiasts didn't like it very much either. So I decided to try my

hand and design a few swords and work with some people I had met over the years to see what could

be done. The end result was the SBG custom Katana and the Proswords

collaboration (you can read about this and all the other various projects we have been involved with here).

While the swords I made with Proswords were well received and quite

impressive, the business itself kind of fell apart when it branched off from SBG and collapsed completely a few years later. The SBG Custom Katana fared better, though was temporarily offline from 2019 until December 2024, but it is a budget, entry level offering.

While these projects were different, the problem was as good as they might have been/are – these swords are ALWAYS held back by the final price point we had to aim for. We achieved a lot, like alternating ito, real boshi, a geometric yokote on the kissaki, etc but when you are trying to keep the price close to $300-500 – normally there are a lot of options you have to leave on the table.

Take, for example, laminated blades. Cheness tried this with the Higo, and while the product was good, they had to trash too many swords each time they did a production run, and it just got too expensive, because it is not the kind of process blue collar workers can consistently perform.

Ultimately, to make a complex laminated blade or even a good folded one, you need a master smith to make it or you end up with slag, poor micro welds air pockets and various weak points.

Example of the cross section of a poorly folded blade. I can count at least 3 major weak points in this cross section alone. How many can you see?

Example of the cross section of a poorly folded blade. I can count at least 3 major weak points in this cross section alone. How many can you see?The word ‘Master Smith’ has been BADLY abused by sword marketers over the years.

Who can forget this classic line of total BS marketing:

|

“Ryumon Swords are hand Forged and by master craftsman with years of experience from Longquan. These master sword smiths (my italics) combine modern knowledge with traditional secrets to produce superior quality handmade Samurai Swords with enhanced durability, sharpness, and exquisite craftsmanship. Each Ryumon Sword is a fully functional, battle ready Samurai Sword” – all yours for only $180.. |

We wish.. And CEO's get the same salary as managers right?

Long story short, there is no way that a Master Smith COULD sell a sword for ANYWHERE NEAR that price.. Heck, most of them wouldn't even get out of bed for that much.. (the highest level masters in China can literally charge millions of dollars to extremely wealthy clients - so be very cautious when you hear the word 'Master Smith' being bandied about on swords at entry level prices).

The Wind Katana, supervised by Chris Zhou

The Wind Katana, supervised by Chris ZhouThe closest the market ever got to a true 'cheap' Master Smith sword was Musashi swords Wind Katana

(pictured right) which was made by senior apprentices under the direct supervision of Master Smith

Chris Zhou – but was canned by Mr. Zhou because he thought it was being

sold TOO cheaply and was damaging his reputation in the process.

But while it was definitely an impressive sword, it certainly wasn’t MADE by a master smith.

Master smiths almost always only make one off custom work, or small runs at the most. These guys are few in number, university educated, and extremely PROUD of both their position at the forge and the blades they hand forge.

Anyway, it was during these heady days that I had my own first encounter with the kind of work these master smiths can do in the form of a Chinese Dao - which WAS made by Mr Zhou..

I’ve never reviewed this Dao, because it’s not a production piece and never actually went into production – but I actually consider it to be one of my favorite swords in my personal collection. From memory, it was priced close to the $2000 mark. But it was incredibly fast, felt

totally solid and cut like a dream.

Even though it is a single handed sword, it cut better than ANY of the Katana I have ever reviewed at SBG until recent years. So it begged the question, what would one of these Master smith made Katana be like!? What else could they make?

No-one was selling them, and I imagined how cool it would be to be able to offer swords like this to the to the SBG community so they could experience how cool and well made these blades can be!

True enough, they would not be for everyone, but they were also developed in response to a question I was asked over and over and over again..

THE SAME OLD QUESTION

On the SBG Japanese swords page there is a ‘caveat and disclaimer’ that more or less can be summed up as 'you can’t get a Ferrari for the Price of a Pinto'. And its the same with swords. You can't get a $300 sword and expect it to keep up with a $5000 Nihonto.

But for around $1000, a lot of options for high quality swords start too open up. So the next logical question is, what are you supposed to buy for that $1,000?

You see, spending more money is not necessarily a guarantee of getting a better sword. And it certainly isn't a guarantee of getting one that was made by a master smith. However Ronin Katana was making waves with their unique Soshu Kitae laminated blade series, which were all priced at around the $1000 mark - and it was from this base that Project X began it's momentous journey...

FAST FORWARD TO 2012

the project begins in earnest

Chris Scoggin from Ronin Katana had been working with some of the qualified, bona-fide Master smiths in Longquan province for some time to create his Ronin Elite line. While reactions to the blades have been mixed (there is a detailed review with the pros and cons of these swords here at Way of the Samurai.com) we were confident that with the right quality control in place we could offer an even better version of these blades.

So what kind of blades are we talking about?

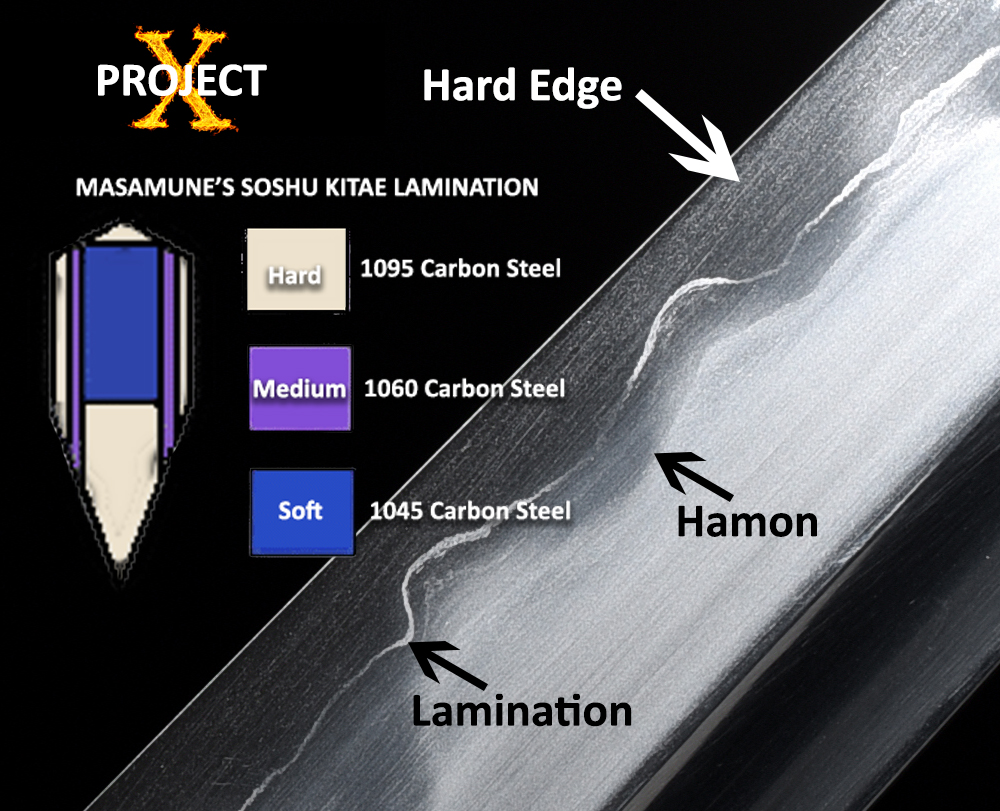

Well, what made them stand out is they are made using the most advanced lamination method ever created - it's invention credited to the legendary Masamune (click here to read more about famous historical Japanese sword smiths). A lamination technique known as Soshu Kiate (5 panel laminate)

The concept is to create a blade with a hard and sharp edge with a jacket of hard steel over a medium, durable layer and a soft, flexible and shock resistant core. When combined with differential hardening, the effect maximizes the blades cutting ability (many people think it is FOLDING that makes the difference, but these days folding is purely cosmetic). Lamination, when done correctly, can take a well made differentiallly hardened traditional style sword as close to a Nihonto as you can get.

So in 2011 we decided to try our hand offering these elite level blades in the SBG Sword Store - and in short order we drew up our plans for the first trial run of Project X Japanese..

PROJECT X Japanese - Version 1.0

Originally, we aimed for the first swords from project X to be available in Jan/Feb 2012. However, the timing of the launch wasn't quite right. It was close, but there were a few additional tweaks were needed one the first prototypes, so we could get the weight, balance, etc spot on.

We already had a pretty good idea of what to expect. But we needed to see first hand how each upgrade would improve the sword - and when it came to upgrades, we held nothing back. Instead of setting a target price and working backwards, we told them what we needed, nearly fainted when we heard the total costs - and said 'go for it' adding the smallest mark up to cover our time and expenses (more on this later, it appears that our partners at Ronin Katana were not entirely honest about the cost price that SBG paid, and while we operated on a tiny mark up, they were double dipping and making at least twice what we were in a very unequal partnership.. Like I said in the intro, there were some dramas)..

Anyway, the end result from the customers point of view was very encouraging - the first years the forge did it's best work - creating stunning, carefully hand crafted Soshu Kitae

laminated blades with real hamon, premium top of the line fittings, and then every extra you can imagine - topped off with Buffalo horn saya, premium quality full

wrap rayskin, Black iron fuchi/kashira, Premium black silk ito,

(alternating, with hishigami triangles to ensure perfect shaping) over a FULL rayskin wrap with EVERY sword..

You name it. These swords had it - no holds barred, no expenses spared. And offered only just above our cost price to give you truly out of this world value for money..

Rarely seen - a full rayskin wrap - default with every blade

Rarely seen - a full rayskin wrap - default with every blade The first two models in Project X Japanese

The first two models in Project X JapaneseWhile the first lot of each Katana line could be pre-ordered, the first time around there were no custom options at all. Just the designs we created ourselves.

Why? Well, to quote Chris:

|

"Project X is a production run of swords using elite blades but with only two different fitting sets. They are made to specs decided upon by Paul and I, and include more bells and whistles. Like the elite line, there are no options for customization. Working with ranked master smiths is very expensive, as these are highly educated and respected individuals. Because Ronin is a large company, I was able to negotiate a set rate per master per day, not per piece." |

However, over time it became clearer that people WANTED to ability to customize these stunning blades to truly make them their own. After all, we had already raised the bar in terms of quality and upgrades. So why not take it all the way..?

It took a LOT of pushing, the forge simply did not want to do it - it was too much bother - but we did not give up, and when they finally agreed Project X Japanese came to full maturity.

The original base models were still there, but each one had a selection of suggested customizations (though you could mix and match as you like) - and we even added some elite cusomizations such as leather ito wrap, rayskin wrapped or mother of pearl inlaid saya, etc as optional upgrades.

Anyway, from this flagship product, Project X had found its feet. But the road forward was not always a smooth one - here's the blow by blow account of how Project X evolved and changed over the years until the present day..

TIMELINE - CONCEPTION TO TODAY

August 17, 2012 - Pre-orders commenced for a limited run of the first Shoshu Kitae limited edition designs.

August 30, 2012 - Pre-orders closed, and the first batch of Project X Katana went into production.

September 26, 2012 - Made a visit to the forge to inspect production and meet the master smiths personally.

The author inspecting the first generation of Katana with the forge owner. Clearly happy with the results.

The author inspecting the first generation of Katana with the forge owner. Clearly happy with the results.January 3, 2013 - The first shipment lands, the swords inspected and shipping to all the customers who pre-ordered was complete as we prepared to take a second batch of limited availability orders in late January/early February.

January 29, 2013 - The sale of any less than perfect stock commenced with a scratch and dent sale..

PROJECT X CHINESE (DISCONTINUED)

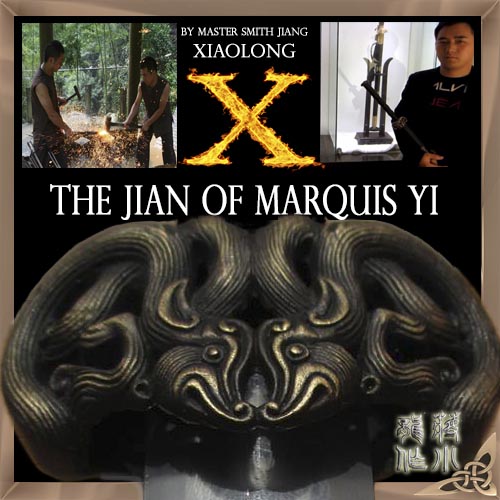

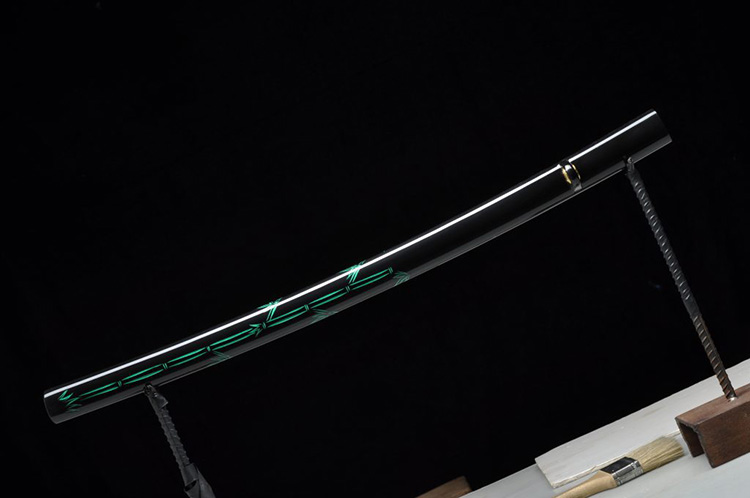

April 17, 2013 - We take a new and exciting direction with the launch of the Jian of Marquis Yi, a truly world-class, heirloom quality Chinese Gim based on an ancient antique and brought to life by the Jiang brothers, most notably one of the youngest smiths to be recognized as a level 2 smith (there is one more level above 2 - and level 3 smiths are considered to be living national treasures).

30th June, 2014 - after much anticipation, the second Project X Chinese Sword, the Dragon Dao, was made available for pre-order.

Feb 4th-17th, 2015 - Pre-orders commence for a new round of Project X Japanese, including a re-release of model #001 and a new all black styled model #003.

18th May, 2015 - Some pictures from the forge, blades now in the final polishing phase by certified master polishers!

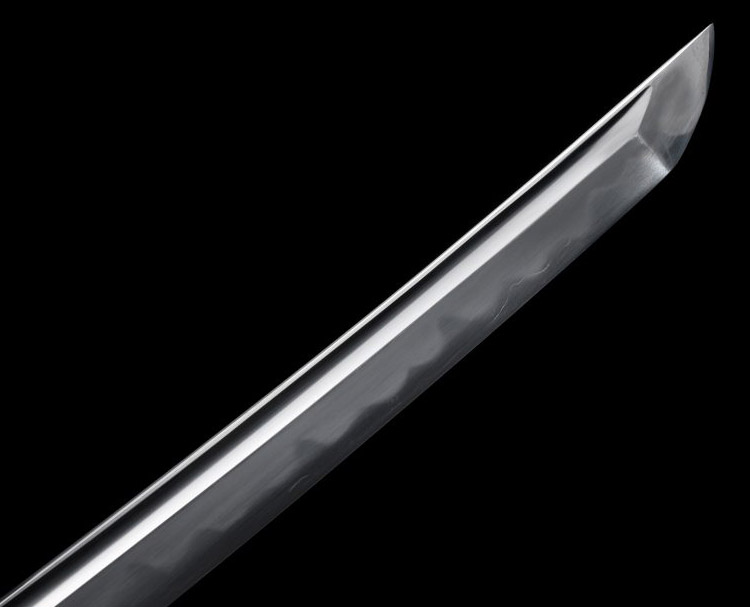

One FULL day of polising per sword by a Master Polisher

One FULL day of polising per sword by a Master Polisher One of the Fine Grit Japanese Finger Stones for final hadori polishing

One of the Fine Grit Japanese Finger Stones for final hadori polishing20th July 2015 - Project X Japanese swords clear customs in the USA and are sent to pre-order customers. Landed stock sells out within 24 hours to members of the Project X mailing list..

30th August 2015 - Project X Japanese is offered one last round of pre-orders until September the 24th.

24th March 2016 - Project X launches pre-orders on 3 new Japanese blades (and an upgraded version of the Chinese Dragon Dao) due to arrive late June 2016.

2016 Branching Out:

Project X - Forge Direct is Born!

1st July 2016 - Project X branches out with a series of semi custom and made to order models of Japanese and Chinese blades with a new branch under the Project X umbrella - Forge Direct!

There were a few growing pains at the beginning, but this offshoot project based on the same basic principle as Project X later prove to be a big big game changer, and i the end saw 2 huge forges and 1 small but highly skilled Master Smith (Michael Ye) start working with us. More on this later..

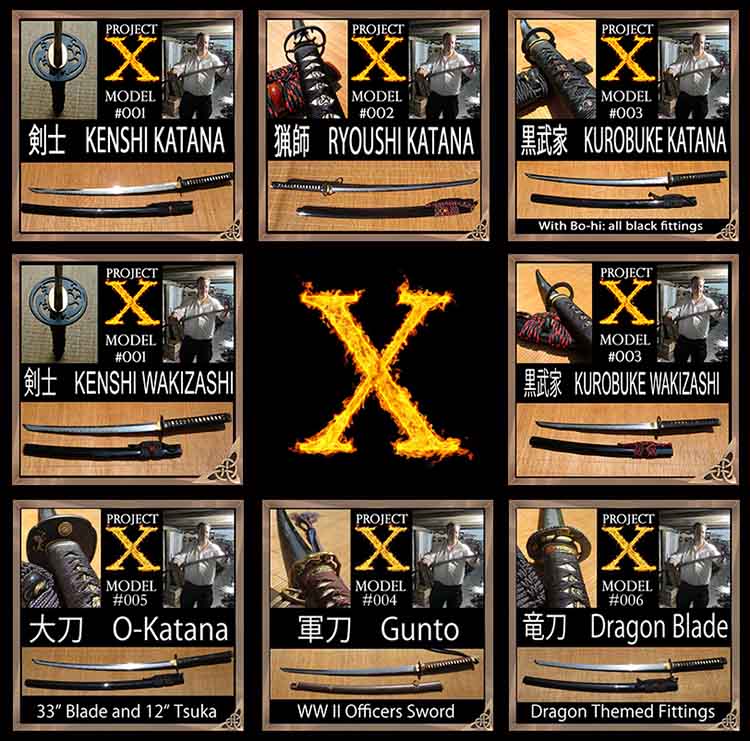

26th June 2017 - Project X Japanese, the classic series (models 1-6 and the Ko-Katana/Wakizashi variations) were made available again and orders filled to maximum capacity over a ten day period.

11th October 2017 - A Major environmental overhaul instigated by the Chinese government hits the project hard, effectively causing a temporarily shut down as any polluting forges or component makers are forced to clean up their act or be shut down. It's a good idea to be clean and green, but it was a bit heavy handed and we nearly were forced to terminate the project..

3rd February 2018 - The dust settles from the shakeup, and production not only resumes but is boosted by the addition of several new product lines to Forge Direct with a Mega Sale and special offers on a new Fantasy Sword line by Master Ye 'Michael' Jie in conjunction with a new website in development, "Legendary Swords.com". (Unfortunately, the interest by the sword community was not enough to sustain justifying keeping this Fantasy project open and it was cancelled in May 2019).

2nd September 2018 - A new collaboration with Jeffrey Robinson, skilled sword maker, sees us taking a high end Feathersteel/Windsteel blade and decking it out with his amazing custom made bronze fittings as part of the Legendary Swords Project. Below is a picture of the prototype of what became a single one of limited edition run of 20pcs.

19th January 2019 - Seraph Aegis become available to buy.

9th May 2019 - CUSTOM PROJECT X - Or Project X Japanese 2.0 - begins. Limited Trial re-release of the ORIGINAL 6 Project X Katana designs, but now made to order and with a large number of customization options. Made to order with a lead time of approx 3-4 months (though it can be shorter or significantly longer, such is the nature of any custom made item - so as ALWAYS with custom swords made from scratch, don't order if you are not truly committed to your sword).

Some of the iron tsuba available

Some of the iron tsuba available Two Master Smiths work side by side to make each blade

Two Master Smiths work side by side to make each blade Premium EVERYTHING

Premium EVERYTHING Hishigami triangles used for the ito, full rayskin wrap - the works

Hishigami triangles used for the ito, full rayskin wrap - the works Truly a beautiful blade - geometric yokote, prominent boshi, hand carved bo-hi

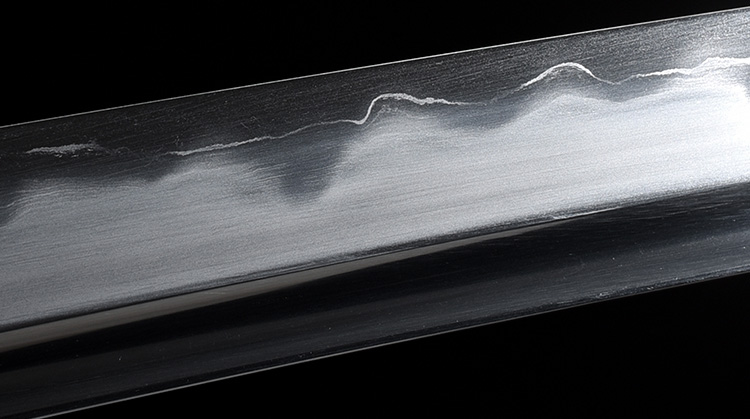

Truly a beautiful blade - geometric yokote, prominent boshi, hand carved bo-hi Close up of the interplay between hamon, lamination - and in this case - the hada from folding

Close up of the interplay between hamon, lamination - and in this case - the hada from folding6th October 2019 - the second round of Project X Japanese begins, this time with 30 pre-order slots available and a longer, more realistic turnaround time (3-4 months) as well as three new models.. At the same time, Forge Direct Japanese - whose swords are made by Project X's biggest competitor, have stepped up to the plate with lower prices and even more custom options..

AND THEN

Along Came COVID-19...

Then along came 2020 - and the normal one month Chinese New Year Shutdown continued for month after month as the SARS-COV2 Pandemic brought everything to a screeching halt..

Project X Japanese, which as supposed to take new orders in February was delayed for 6+ months, Forge Direct orders continued for as long as possible until International shipping ground to a complete halt - and supply chain issues bit the industry hard so that by the 23rd of June we had to put a halt to ALL Forge Direct Orders until the backlog was back in control.

However this 'dead' time was not been wasted.

Both Forge Direct Japanese and Project X received some serious upgrades during this time. For example full rayskin wrap options.

The biggest issue(s) - as there are two of them:

- Currently we can ONLY ship to USA addresses and

- The cost of shipping has skyrocketed, way more than double and closer to triple the shipping costs. Indeed, everything has gone up - from new levies at the forges end they expect US to pay, to less staff but higher wages, and the previous prices are just not sustainable anymore. So I am afraid that a rise in price is inevitable, but will be as low as we can possibly make it.

It was a tricky time, but persist we must. And persist we did..

23rd August 2020 - Project X Japanese opens for the first and last time in 2020. Fully paid pre-orders maxed out within 4 days.. Below are some pictures of the swords from this batch being polished and assembled over a period of 4 months as advertised.

25th May 2021 - Another round of Project X is offered to our subscribers list and nearly hits maximum capacity before we can make it available to the general public..

30th May 2021 - Forge Direct Chinese comes back online - as does Master Michael Ye who returns from retirement earlier in the year and releases two new very unique designs in the style that he has become famous for.

28th November 2021 - Numerous supply chain issues converge on Project X and orders are coming in much slower than anticipated. Additionally, higher costs and a drop in overall quality forces us back to the drawing board and we negotiate with the smiths who produce Forge Direct to find a capable alternative supplier different than the Ronin Elite line forge.

Prices - and overall quality - are higher on this proposed line, but behind the scenes we work to produce some prototypes and are delighted with the result..

1st March 2022 - Project X, the next generation, is announced in the March edition of the Sword Buyers Digest as final preparations are made for a relaunch of an improved version of Project X..

8th May 2022 - Project X the Next Generation launches its first batch. While initially looking like it would be batched like previous issues of this line, after reaching 50% of the forges maximum production capacity, orders reached a point of equilibrium and the decision was made to offer it all year round from the 22nd of May (until and unless orders exceed the forges ability to supply them).

The Great Reset

23rd October 2024 - the rising costs and falling profit margins from Project X and Forge Direct had caused us a niggling doubt that something was off with our partnership deal with Chris Scoggin at Ronin Katana.. A few off hand comments made me start to question their role as 'gatekeepers' of the project, and too late I realized that I had been operating from a position of trust with a 'gentleman's agreement' that had been rotten from the start..

It would seem that our 'equal partner' at Ronin had used their position to inflate the forges invoices at the front end and were also receiving equal shares of the modest profits at the back end, effectively secretly making at least $2 for every $1 SBG made (we suspect it is actually higher than this, but it is hard to prove as they refused to share the forges original invoices)..

This all came to a head on the 23rd of October, when having become aware of this grand deception, we immediately severed all ties with Ronin Katana and Project X and Forge Direct were also taken offline..

It was a very troubling time for SBG, while our customers were not directly effected by the deception that Ronin Katana has been running on us, if we had known then what we know now, we could have packed in more features and lowered the price..

30th December 2024 - After months of retooling from the fallout caused by the Ronin split, Project X and Forge Direct FINALLY come back online with way more features, NO additional upgrade fee requirements (so one flat rate price for ALL options) and many free upgrades (such as a full rayskin wrap on EVERY sword by default, and close to double the number of available customization options).

The final cut

By the 4th of November 2025, after years of turbulence, trade war fallout, and mounting financial losses, Forge Direct has officially been retired.

The project endured more than a decade of mythic steel and community-driven innovation, but the economic climate proved too volatile to sustain.

Only the flagship remains—a legacy piece with no future plans for expansion or revival. Project X continues in name alone, a testament to what was built, and a quiet farewell to what could no longer be carried forward.

Thanks for reading and even better, thanks if you became part of SBG and Project X history.

Buying Swords Online Can Be DANGEROUS!

Find the Best Swords in the:

Popular & Recommended ARTICLES

The ONLY true free online magazine for sword enthusiasts. Delivered once a month on the 1st day of the month, no filler and no BS, just the latest sword news & info delivered straight to your inbox.