Recent Articles

-

Christmas Sword Buying Guide 2025

Dec 03, 25 10:53 PM

A Good Battle Ready Sword...

The Basics

Many online sword sellers bandy the terms Battle Ready Sword and Functional Sword around like its going out of fashion. But just because a sword is called Battle Ready by a merchant doesn't necessarily mean that it can take the kind of punishment you might want to dish out to it

Before you part with your hard earned cash and decide to buy what is being described as a battle ready sword, you'll need to know the answers to four very important questions.

Otherwise, you'll have no way of knowing how to seperate the truly functional swords from the wanna be's (other than taking a sword merchants word on it) - and you could easily wind up with a 'real' lemon...

Type of Steel and Tempering

Most swords that gleam or shine are made of stainless steel, and anything made of stainless steel is not a real sword but a decorative 'sword like object' (SLO).

While stainless steel swords are very low maintenance, their length makes them brittle and they cannot take nearly the same punishment as a historical sword.

Real swords are ALWAYS made from Carbon Steel. Below are the two most common types of Carbon Steel battle ready swords are made from:

- AISI 10xx: This plain carbon steel is an excellent choice for swords, (especially Japanese ones) and contains iron, manganese and carbon. The actual carbon content expressed as a percentage in the last two digits i.e. AISI 1050 has .50% Carbon, AISI 1070 has .70% Carbon, etc. The higher the carbon content, the harder the steel. The lower the carbon content, the more tough the steel is.

- AISI 5160: Considered by many sword experts to be one of the best materials for swords in general (and European style swords in particular) this steel alloy has a low (0.7%) Chromium and Silicon (0.2%) Silicon content making these swords tough, durable and slightly more resistant to corrosion than the AISI 10xx.

There are several other types of Carbon Steels, Spring Steels, Tool Steels and others - however the AISI 10xx and 5160 are the most common. For more detailed information on the different types of steels swords are constructed from, check out this article Sword Steels 101.

Anyway, just because a sword is made from Carbon Steel doesn't necessarily guarantee that it is battle ready. For a sword to be functional, it needs to be properly heat treated.

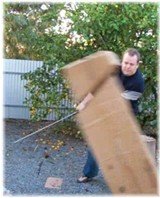

The author, flex testing a sword

The author, flex testing a swordThe goal of heat treating is to achieve a balance between toughness and hardness. Too soft, and your sword gets cut in two. Too hard and the sword snaps in half! It's a delicate balancing act, and heat treating incorrectly can totally ruin a sword.

Measuring Hardness

A swords relative hardness is measured by a number the Hardness Rockwell Cone (HRC)..

High numbers indicate a harder material. In general, European style swords should have a HRC of 45-50. Differentially tempered Japanese swords (meaning the cutting edge is harder than the back of the sword) should have an edge of HRC58-60 and a back of HRC38-40.

Some businesses or websites boast about the quality of the steel but don't mention how or if the sword was heat treated. This can sometimes be an indication that it hasn't been heat treated properly at all !

In fact, I've seen some so called battle ready swords from Pakistan which are described as High Carbon Steel but because they have not been properly heat treated, they are as soft as butter!

Technically, I'd say that the people selling them figure these swords can be described as battle ready because they are made from High Carbon Steel, but for all practical purposes, you might even be better off buying a stainless steel wall hanger sword like object!

It's practices like this that makes it all the more important to buy your battle ready sword from reputable dealers made by well known and respected manufacturers that have a solid reputation for using good quality steel and doing a thorough heat treatment.

Of course, the easiest way to find such sellers is to check in the:

Now, thats not to say that if you happen to stumble upon a battle ready sword made by a relatively unknown manufacturer you shouldn't buy it. Just be a little wary, and if it doesn't say in the description how the sword was heat-treated and you aren't sure, ASK!

Hilt Integrity and the Tang

Many cheap swords are just an accident waiting to happen.

Any sword is only as strong as its weakest point. And the weakest point of most swords is the handle: specifically, the swords tang, and how it is attached to the blade.

A European battle ready sword needs to have what is commonly called a full tang. However, the term 'full tang' can be a bit misleading.

A 'full tang' is really describing two halves of a handle that sandwiches the tang on either side such as you see on your everyday kitchen knives or on a machete.

What is meant in the classical sense of a 'full tang sword'

What is meant in the classical sense of a 'full tang sword'What most people are referring to when they say 'full tang' is a tang which is forged as part of the sword and then peened or threaded to the pommel - not just a thin rod that's welded on as an afterthought (i.e. "rat tail tang").

A classic rat tail tang

A classic rat tail tangJapanese swords often have tangs (called Nakago) that are locked (but not actually held) in place

to the handle with one or two pegs called Mekugi. Half tangs and

rat-tail tangs are especially prone to breakage when the sword is

forcibly swung and cannot stand up the stress of making contact with

another object.

Sometimes you can plainly see by looking at a photo of a sword what kind of tang it has, but more often than not it isn't quite so clear as the tang is hidden away in the handle. So again, if it doesn't say so in the description - or if you don't know or trust the manufacturer (some are good enough that every sword is tempered!) - it's safer to assume the worst ...

Conclusion

RELATED ARTICLE: The 3 basic characteristics here will ensure a durable and functional sword, but not necessarily one that handles or cuts very well. For two more important, but more subtle considerations, click here

Steel and Tempering, Handle and Tang these are the four essential "yin and yang" qualities of a functional battle ready sword.

While simply looking for these qualities may not guarantee you a 'perfect' battle ready sword, it will at least weed out those that don't stand a chance...

And as to the rest of them, well - that's what SBG is for now isn't it! ;-)

I hope this information on selecting a battle ready sword has been helpful. To Return To WARNING: Do Not Buy Swords Online Until You Read This from A Good Battle Ready Sword: The Basics, Click Here.

Buying Swords Online Can Be DANGEROUS!

Find the Best Swords in the:

Popular & Recommended ARTICLES

The ONLY true free online magazine for sword enthusiasts. Delivered once a month on the 1st day of the month, no filler and no BS, just the latest sword news & info delivered straight to your inbox.