Recent Articles

-

Christmas Sword Buying Guide 2025

Dec 03, 25 10:53 PM

Quest for the most affordable traditionally forged Katana Swords

DISCONTINUED

This sword has been discontinued and is no longer in production or available, but is preserved on the site for informational purposes.

Cheness Cutleries Katana swords are for the most part what you'd call "Dojo cutters" - in other words through hardened, well balanced swords designed for frequent cutting of Tatami mats and other traditional targets.

Not art swords. Not for display. But for dojos - real hard wearing cutters.

However, during their early days they experimented with a sword they named the Kanbai (Winter Plum) which was designed for the general interest collector - a cheap 1045 carbon steel blade that had been clayed and differentially hardened in the traditional way. After all, they were breaking new ground - so why not get the forge to try something balanced between the raw steel chair puncturing functionality they were getting a reputation for and an authentic Nihonto with it's natural, non-enhanced hamon line..?

The project turned out well, and the Kanbai was soon gone when Cheness started using their revolutionary 9260 Spring Steel and it quickly evolved into the Kaze Katana..

But it was the Kanbai that started it all for me - because it was the first time I had seen a non-Hanwei frosted hamon - and I liked what I saw...

Cheness Cutleries Kanbai KATANA

classic Review (2005)

by Paul Southren

|

Steel Weight Point of Balance Price Range |

1045 Carbon Steel 2lbs 9oz 5.75" from tsuba US$219 to $249 |

As you may know, Cheness Cutlery Katana swords concentrate on producing the very best 'bang for your buck' blades.

However, the reason that they are able to sell their swords at such a low price is by keeping their margins extremely tight and selecting fittings more for their overall functionality rather than flashy 'bling bling' qualities, concentrating instead on producing properly forged blades.

Since Cheness cutlery Katana swords can be disassembled in the traditional manner (by removing the mekugi pegs) upgrading and customizing this swords is always an option. But once all is said and done, the fittings aren't all that bad and certainly a lot nicer than many other Katana swords in this price range.

The tsuka hilt itself is Cheness Cutleries stock standard antiqued brass 11" model, described below.

The Tsuka Hilt

Starting from the bottom of the sword and working our way up, the brass 'pommel cap' (Kashira) is probably one of the least attractive parts of the hilt assembly. Looking at it from the very top, there is a clear molding line (though from the sides the mottled dark pattern looks great).

The cotton wrap (Ito) of the handle is traditional looking, symmetrical and comfortable in the hand - though certainly not as tightly bound as it could (and should) be. On the positive side, unlike just about all other Katana swords available at this price point in 2005, under the Ito is a long panel of real ray skin (called 'same', pronounced 'sah-may') - which looks fantastic and certainly beats the plastic raised white bubbles seen on most other production Katana. The only problem is, on occasion it is obvious that two panels of ray skin have been used, though this is rare and a forgivable cosmetic flaw at the worst as a single rayskin is quite expensive, so off cuts can and are used to keep the price where it is.

On either side of the hilt in between the handle wrap and the ray skin is a single brass ornament ('menuki') - which for all Cheness Cutlery Brass Hilts is a 2 and 1/2 inch long bronze figurine.

At first, depending on where the Menuki is positioned within the braid, it can be hard to identify and looks kind of 'spidery'.

But due to the slightly loose Ito wrap, it is not too difficult to move it along the hilt, and once in position you can make out that it is actually a cool looking horned, bat winged Japanese Oni (demon) laying on his stomach with his fierce looking head in his hands.

Years later I would encounter this particular menuki at a sword store in Kyoto. Naturally, I snapped up a pair - it's a classic menuki design apparently.

The hilt terminates to the hand guard with a very nice looking brass collar (Fuchi) which matches the mottled design of the pommel cap (minus the ugly cast lines) - and the whole assembly is firmly connected to the tang with two wooden mekugi pegs.

I am in two minds about the attractiveness of the hand guard (tsuba).

Essentially it is a solid cast brass oval with four slightly indented 'corners' (symbolizing the plum flower) and a single slot along the right side (assuming you are holding the sword with the cutting edge facing down). The brass guard is then decorated with a gold brushed pattern of traditional Japanese ivy like swirls and 4 solid plum flowers on each side. In the right lighting, the gold pattern on the tsuba looks very impressive against the darker brass metal. But in bright light, there is something almost a bit 'plasticy' about the overall appearance and the definition on the very edge of the tsuba circumference (in other words from the side) is often rather blurred and a bit messy.

While the fittings might not be perfect, they are purposefully kept as cheap and purely functional as possible, as the real beauty of these Katana swords is in the blade itself...

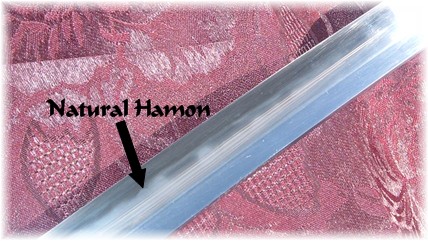

The Blade and My First Look at a Natural Hamon

Now we are getting down to business - because (excuse the pun) the blades are where Cheness Cutlery really shine...!

Mount this blade in premium koshirae (fittings) and I felt that you could probably get away with selling it for US$700 or so. But that was not Paul Chen's intention - his mission is to produce the best quality blades at the lowest possible margins so that anyone who has a love for genuine Japanese Katana swords can afford a high quality, practical blade. And that is exactly what the blade of the Kanbai is...

Like I mentioned briefly at the start of this review, the blade is differentially hardened by hand claying the edge with a much thinner coat than the back and giving the sword a second tempering before oil quenching (rapid cooling). Essentially, this process transforms the steel on the very edge of the blade into marsenite and pearlite, which is considerably harder than normal steel and is without a doubt the most common and traditional method used in forging traditional Katana swords.

As a by product of this process, the edge of marsenite and pearlite has a slightly cloudy, milky appearance known as the "hamon" which is traditionally brought out to its full potential by a very expensive and labor intensive polish (it's interesting to note that traditionally, an apprentice sword smith had to train 7 years before he was considered skilled enough to forge his first sword, while a polisher had to train for 8!)

Now I am not going to go into it too much here. But around 90% of all production Katana swords have a cosmetic fake hamon that is simply used to increase the swords visual appeal. This can vary from the nasty "shark tooth" hamon seen on wall hanger Katana swords (made by a wire brush wheel and a uniform stencil) to the acid etch seen on the closest competitor to the Kanbai, the Practical Plus Katana (which IS a differentially hardened blade, but with such a coarse polish job that the natural hamon is invisible).

The Kanbai is a very rare sword for its price range. The hamon is unetched and natural. But by the same token, it is also not polished in the traditional way - otherwise it would simply be impossible for it to be available at its current price...

The Hamon is doesn't jump out at you - it is very subtle. But as you can see from the pictures below, when looked at from the right angle, the play of its border is very lively, beautiful and most importantly, it is real - what you see is what you get.

As for this Katana swords weight and balance - it depends on what option you choose - Bo-hi (fullered/blood groove) version or non-fullered.

However, both versions handle exceptionally well. The weight to balance ratio is spot on, and they handle like traditional Katana swords should - fast, powerful and agile.

The Kanbai with bo-hi weighs in at 2lbs 3oz while without it the sword comes in only 1oz heavier. The major difference is in the point of balance, which at 6" from the hand guard on the full version and 5" with bo-hi.

The major difference between is that the bo-hi version makes a much more impressive whistling sound when cutting the air. Neither is superior to the other, it is simply a matter of personal taste and intended function. To quote Paul Chen:

|

The no-fuller version blade has a more forward center of gravity heavier weight. This type of blades have more lateral strength and are easier for tameshigiri from the weight and the reduced drag. Whereas the variant with fuller is better for kata practice, the no-fuller variant is better for cutting practices. |

Personally, I like them both for different reasons. My Kanbai with bo-hi is a great looking practice sword, but for backyard cutting and a more solid 'traditional' look, I lean slightly more towards the non-fullered version.

Speaking of backyard cutting...

Test Cutting with the Kanbai

The Kanbai's keen edge and solid construction make short, effortless work against all light targets. So it should go without saying that these Katana swords sail straight through anything from watermelons, pumpkins, etc without so much as a blink of an eye. Even cutting an aluminum can is not a challenge (though, like all swords, such targets can cause minor cosmetic scratching of the blade).

Naturally enough, cuts through many a favorite target for the backyard cutter, a water filled soda or milk bottle, are no challenge either. But what makes the Kanbai so unique is the definition of this Katana swords cuts. Each stroke leaves a much crisper and cleaner cut line than I have seen on any other sword in this price range, a testament to its sharpness, speed and blade geometry.

Personally, I've found that cutting one soda bottle or milk jug is rather ho-hum, especially considering that a properly differentially hardened Katana can most easily take on several at a time - without sending the bases all over the place like bowling pins. Multiple targets like these are a whole lot of fun, and even though you might not as get as much mileage out of them as you can cutting them one at a time, the extra challenge is well worth it and you can clearly see the blades cutting course from one jug to the next.

Such targets are very much a matter of course for Katana swords like this one and present virtually no risk to the blade. You could cut these targets day in and day out without losing the swords keen cutting edge or suffering anything more than a few surface scratches to the polished steel blade. But for my purposes, I had to push the envelope against a few more traditional targets.

The first of these were lengths of bamboo/river cane with an average thickness of a little over 1" slotted into my cutting stand.

River cane is actually quite a tough target to cut. You need a very sharp edge and a nice cut to go through easily in one hit. But even river cane was an easy target for the Kanbai.

While the downward strokes of my PPK against river cane were somewhat ragged (though the upward strikes were very crisp) nearly every cut by the Kanbai was amazingly clearly defined (and the occasional bad ones were more a testament to my lack of skill than a fault of the blade, after all I am more of a collector and backyard cutter than a serious JSA student!).

For a demonstration of just how easily and cleanly the Kanbai cuts bamboo, check out the video below - if it can cut for ME like this...

So after these simple tests, the time had come to really put the Kanbai to the test where so many other differentially hardened Katana swords fail...

It sounds funny I know, but perhaps the biggest equalizer of production differentially hardened Katana swords is the thick cardboard mailing tube. In fact when my friend Jason from Arms of Valor was test cutting against these targets, he noted how difficult they were to cut. In fact, he said that when he attempted to use his trusty Practical Plus Katana, which he said was his best cutter, it took a serious set/bend and had to be straightened out by hand...

"Here was a worthy target to really push the Kanbai to its limits!"

The target looked intimidating.

I had never cut one of these things before (after all, they are

pretty expensive!) and had no idea what to expect. To be honest, I was

pretty sure that the Kanbai was going to fail. Cutting these things is not anywhere near as easy as it looks, and I had heard that these rounded

shipping tubes can sorely test production Katana swords, blunting, chipping or even breaking them clean in two if the cut's alignment is even slightly off.

So I took a deep breath, shuffling backwards and forwards for a few seconds, and then when the moment felt right, I wound up and let fly!

I felt the target resist. In fact, I swear that I actually saw SPARKS! But in the next moment, there was a stump of the tube flying through the air and when I looked down at the blade, I was delighted!

It was as straight and true as the first day I had bought it!

In fact, the only ill effect was a black smear on the blades surface caused by a shipping label that was on the other side (should have probably taken it off first!) and a few more minor scratches...

But the black mark wiped off with some WD-40 and a cloth.

And the scratches, well I don't know - it's a matter of personal taste, but I actually kind of like my swords with a few minor 'battle scars' (though it would take a lot of shipping tubes like this before it would be anything detrimental).

Overall, I felt that these swords are fantastic value for money, in fact the blade alone is easily worth the price of the entire sword...

EDITORS NOTE AND ADDENDUM

The Kanbai may be long gone, but it's spirit likes on in the Katana swords it passed the torch to - the Kaze Katana series..

Looking at it today, it is a little outdated - after all nowadays Musashi swords have a 1045 differentially hardened Katana for half the price. But I've tested both, and know I would not want to take on the shipping tube with their Bamboo model Katana - it's a light cutter only.

The Kanbai was the real deal.

I hope this information on these Katana swords has been helpful. To return to A Beginners Guide to Buying Authentic Japanese Swords from The sharpest, most affordable traditionally hand forged Katana Swords, click here.

Buying Swords Online Can Be DANGEROUS!

Find the Best Swords in the:

Popular & Recommended ARTICLES

The ONLY true free online magazine for sword enthusiasts. Delivered once a month on the 1st day of the month, no filler and no BS, just the latest sword news & info delivered straight to your inbox.